For an average citizen, the phase “Circular Economy” should sound quite familiar, as many companies, governments entities, and private institutions are promoting it as the model that will transform global economies to be more resilient and more environmentally conscious.

Indeed, Circular Economy can affect and inspire a wide range of business processes like supply chain management, product design, innovation, waste management or environmental impact.

But what exactly do we understand by “Circular Economy”?

Thanks to a global consultation across 100 countries and 19 international organizations, the ISO Standard 59004 has successfully produced an international definition of Circular Economy:

“An economic system that uses a systemic approach to maintain a circular flow of resources, by recovering, retaining or adding to their value, while contributing to sustainable development.”

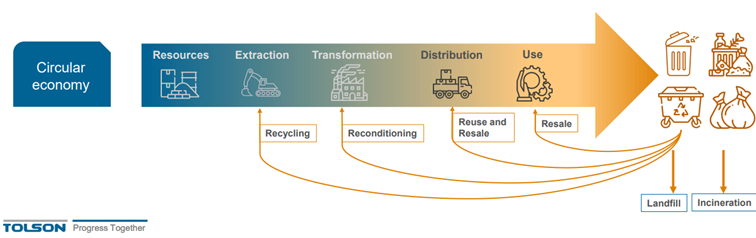

A simple way of looking at circular economy is the idea of reintroducing seemingly obsolete products and materials back into the economic cycle via processes of recycling, resale or reconditioning, instead of throwing them away.

Expanding on this idea, the Ellen MacArthur Foundation proposes the “Butterfly Diagram”, a larger and more holistic model that considers not only industrial cycles, but also the natural cycle, as both play different roles in the economy and the resilience of society as a whole:

At first glance it may seem complex, but the Butterfly Diagram is actually quite intuitive. The diagram proposes there are two cycles in the economy. Each is designed to address the treatment and repurpose of the two kinds of material in adapted ways, so that the most value is extracted in every case:

-

- The technical cycle aims to keep products and materials in circulation for as long as possible through processes such as reuse, repair, remanufacture and recycling. It includes all materials that do not biodegrade (i.e. metals, plastics, etc.) and would go through a post-disposal transformation to be reintroduced in the economy.

- The biological cycle aims at separating nutrients from discarded biodegradable materials and returning to the Earth to regenerate nature. This would include food, wood, some types of textiles, and much more but the biodegradable element is key.

In these two cycles, products can follow a hierarchy of treatment that enables to extend their life cycle and reintroduce materials in the economy, responsibly dispose of biodegradable materials, and effectively reduce waste, pollution, emissions, and overconsumption.

| Biological Cycle | Technical Cycle |

| Cascading: the principle of using biodegradable material for as long as possible as it gets transformed for different purposes in the economic cycle (i.e. raw wood, particle board, wood chips, pulp, etc.) | Recycling: loop of last resort for products that cannot be fed back into the system at end-of-life and are made of high-volume, low-value parts. |

| Regenerating: the opportunity to nourish the biological cycle by feeding back all biodegradable waste to sustain and enrich soils and ecosystems. | Remanufacturing: revalorize high-value, high-cost products at end-of-life by refurbishing the defective parts, instead of discarding and replacing the entire product. Improved product design and predicting PLC would optimize this loop. |

| Reusing: for high-value products, switching to a reuse or redistribution system incentivizes manufacturers to build better lasting quality and focus on manufacturing to increase durability and long-term value. | |

| Repair: based on the premise of fixing something before it breaks and needs remanufacturing. | |

| Sharing: A transversal approach that allows consumers access to high-end products with low-frequency use without owning them. It incentivizes a reduction of mass manufacturing and aims at reducing stocks of unsold products. |

Thus, every product introduced in the economic cycle can, to a certain extent – in full or in parts – be reintroduced to optimize the use of materials, extend their life cycle, and reduce mass production of goods, the use of raw materials, and excessive waste. In this way, this economic model aims at retaining value of products and raw materials by reusing, repairing, renovating, recycling and sharing existing products as long as possible.

Strategies to put a circular economy model in action

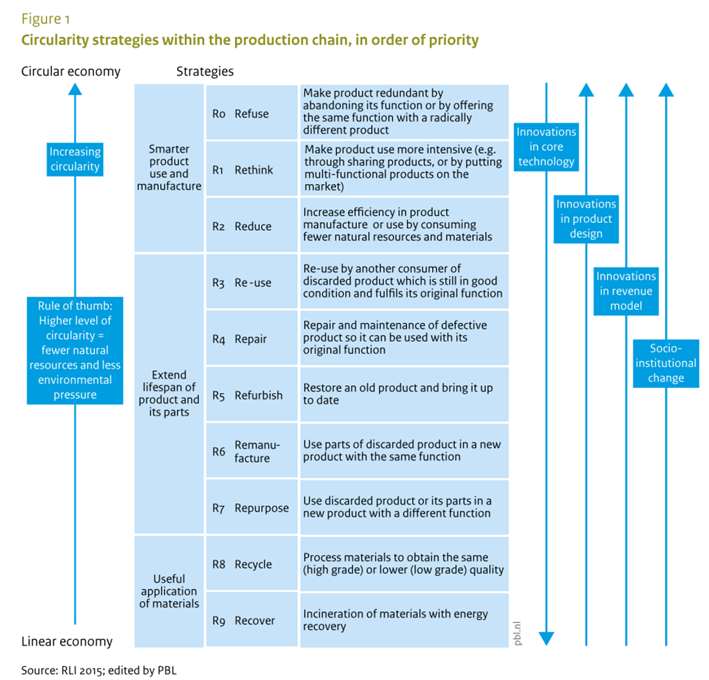

In 2017, the Dutch Environmental Agency proposed a strategic model to address circular economy challenges which defines the steps to design and integrate more circular products, not only in business processes, but across the EU economy.

The diagram below represents the proposed model, which proposes 10 strategies in order of priority, conceived to achieve a circular economy. The model is based on the premise that to reach higher circularity in the economy requires a socio-institutional change. The model proposes that the change needs to happen at the business and revenue model level, as well as at the product design level. As these two progress toward circularity, an economy should move from simply making a useful application (or re-application) of materials (recycle, recover), to the attempt to extend products’ lifespan (re-se, repair, refurbish, remanufacture, repurpose), to ultimately achieve a change in mindset to make a smarter use of products and manufacturing (refuse, rethink, reduce).

Re-evaluating Product Design, Sourcing, and Life Cycles

Looking at the different stages of each cycle according to the Butterfly Diagram, the natural cycle appears simpler than the technical cycle. Yet, implementing circularity in the natural cycle often proves more challenging.

One key reason is that manufacturers continue to create products that mix technical and biodegradable materials in ways that make separation difficult, limiting the ability to reintroduce materials into their respective production loops. Even when circular products are designed thoughtfully, they often struggle to scale – not because of design flaws, but because they operate in an economic system still structured around linear principles.

For example, imagine you want to lower your carbon footprint by cycling instead of driving. You live in a bike-friendly city with government incentives for bicycle purchases. To go further in your sustainability efforts, you buy a secondhand bike. Everything seems great—until a crucial part breaks, and you discover that replacements are unavailable, and modern alternatives don’t fit. When you seek out a recycling or repurposing service for the old bike, you find none exists.

This type of market gap is common. The issue isn’t just product design, it’s the lack of supporting infrastructure. Without a circular value chain, even well-designed circular products can end up stuck in the same wasteful cycle as traditional products.

At a recent TOLSON session, Equans presented their Reuse Corner, an ambitious initiative aimed at optimizing resource efficiency by repurposing materials and equipment across different projects. However, just as an individual trying to repair and recycle a second-hand bike, even engaged and innovative corporate initiatives like Equans’ can encounter similar systemic challenges when trying to scale across a global or even national operations:

-

- Supply chain complexity can make internal reuse challenging for procurement, logistics, and inventory managers used to linear economic model based on optimized for new materials, and business processes that are not designed for tracking, collecting, and redistributing used or surplus resources efficiently.

- Large companies are subject to increasingly strict compliance standards and regulations, which may not always accommodate reused materials – or with which materials may not yet be compliant.

- Circular initiatives require widespread buy-in from employees, suppliers, and customers. If internal teams are used to simply discarding excess materials or defaulting to new purchases, transitioning to a reuse model demands a shift in both culture and operations.

- Trying to repurpose industrial materials might not always find a matching need at the right time and place. Without efficient coordination and digital platforms to bridge these gaps, materials risk sitting idle or becoming obsolete.

For large companies, some solutions to these implementation and scalability challenges rely on ensure that the business ecosystem where products and materials move supports circular economy models, beyond designing programs or mechanisms that make reuse and repurposing available at the corporate level; To achieve this, companies can also:

-

- Invest in tracking and logistics systems to efficiently match supply with demand for reused materials.

- Advocate for regulatory flexibility that allows for safe, compliant reuse of industrial equipment and materials.

- Embed circularity into procurement policies so that teams naturally consider reuse before ordering new materials.

- Develop partnerships with other organizations, suppliers, and customers to create a broader circular economy network.

Balancing Circularity, Profitability, and Design Thinking

For circularity to succeed, it must align with the core principles of Design Thinking: desirability, viability, and feasibility. Circular products must still be attractive to consumers, technically functional, and economically viable. Circularity should not be treated as an add-on but rather embedded into the design process from the start.

At the same time, companies must be strategic in how they market and sell circular products. Overemphasizing sustainability can overshadow other competitive advantages, such as performance, innovation, or usability. A well-designed circular product should be marketed as a great product first, with sustainability as an added value rather than the sole selling point.

Yet, even with strong design and marketing, circularity will struggle to scale if it is not financially viable. Profitability is the key enabler of circularity at scale—without a sustainable business model, circular initiatives remain niche rather than transformational. Circular products must drive economic value by lowering material costs, creating new revenue streams (e.g., resale, repair services, leasing models), and positioning sustainability as a premium feature that attracts long-term customer loyalty. Businesses must shift from viewing circularity as a cost burden to recognizing its potential for financial and operational efficiency.

Finally, businesses must recognize that durability alone isn’t enough. A long-lasting product introduced into a still-linear economy may not achieve the expected impact if repair services, take-back programs, or material recovery systems are lacking. To truly scale circularity, companies must not only design better products but also help build the ecosystem that makes circularity feasible and profitable. By aligning circular design with economic realities, companies can move beyond isolated sustainability efforts and drive systemic change. The future of circularity depends on designing products that are not just sustainable, but also desirable, scalable, and financially viable – proving that profitability and circularity are not opposing forces, but powerful allies in shaping the economy of the future.

Sources

-

- Ellen MacArthur Foundation, The Circular Economy Show, “Circular design essentials: What every designer needs to know”, https://www.youtube.com/watch?v=TkPOtycZyEA&list=PLXT_ozykGValPRypMeuhQe9nBZUvRIEB2&index=6

- Ellen MacArthur Foundation, The Circular Economy Show, “Scaling supply chains in the circular economy with Deborah Dull” https://www.youtube.com/watch?v=zjalt3PE4wY

- Ellen MacArthur Foundation, What is a Circular Economy?, https://www.ellenmacarthurfoundation.org/topics/circular-economy-introduction/overview

- EU Commission, Categorisation System for the Circular Economy, a sector-agnostic approach for activities contributing to the circular economy, https://circulareconomy.europa.eu/platform/sites/default/files/categorisation_system_for_the_ce.pdf

- EU Parliament, Circular Economy: definition, importance and benefits, https://www.europarl.europa.eu/topics/en/article/20151201STO05603/circular-economy-definition-importance-and-benefits

- Financial Times, Corporate buyers still fall for green marketing puff, study finds, https://www.ft.com/content/b4626565-af92-4e64-8fb0-c1b14e3f9b54

- McKinsey & Company, What is Circularity?, https://www.mckinsey.com/featured-insights/mckinsey-explainers/what-is-circularity